Poly Plug Clear Gel

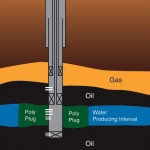

Used for drilling and workover applications, Poly Plug® Clear Gel can be mixed as either a high or a low molecular weight polymer, depending on your well’s specifications and challenges. It is a temperature-activated, cross link polymer product, and can be retarded or accelerated to function within the wellbore BHT from 44.6° F to more than 400° F.

- Right Angle Set Technology at 120° F

- Right Angle Set Technology at 345° F

It is formulated with high concentrations of low molecular weight anionic polymer. When combined with a carboxylate complex cross-linking agent, Clear Gel produces a rubber-like ringing gel structure. The only product of its kind on the market today, Clear Gel is used by more than 50 different operators for casing leaks, gravel pack consolidation, low high permeable matrix and perforation abandonments for plug downs.

Benefits:

- Works where cement doesn’t

- Designed with a low viscosity prior to cross-linking to aid in injectivity

- Effective in full shut-off treatments into rock matrix less than 750 md

- Works by entering the reservoir and reducing permeability, not by simply plugging the perforation as in Portland cement treatments

- Never a drill-out problem, washes out of pipe for easy clean out

- Seals perforations in water zones

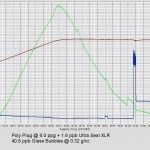

Poly Plug Ultra Squeeze Cement City, OK

The well hit depleted sandstone at 16,000’. Three other cement plugs were pumped prior to using Poly Plug® Ultra Squeeze and the wellbore was on vacuum.

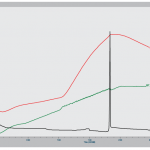

Continue Reading...Poly Plug Ultra Squeeze East Texas

Cure loss circulation and increase mud weight when drilling into the Travis Peak Formation, which consists of fractured limestone. The objective is to cure loss circulation while safely drilling through tectonically stressed shale formations.

Continue Reading...Poly Plug Ultra Squeeze Fort Nelson, BC

Operator was drilling ahead with no losses when a drill break occurred and the bit fell 5’. Total loss of circulation occurred into a fractured sandstone.

Continue Reading...